Listing Details

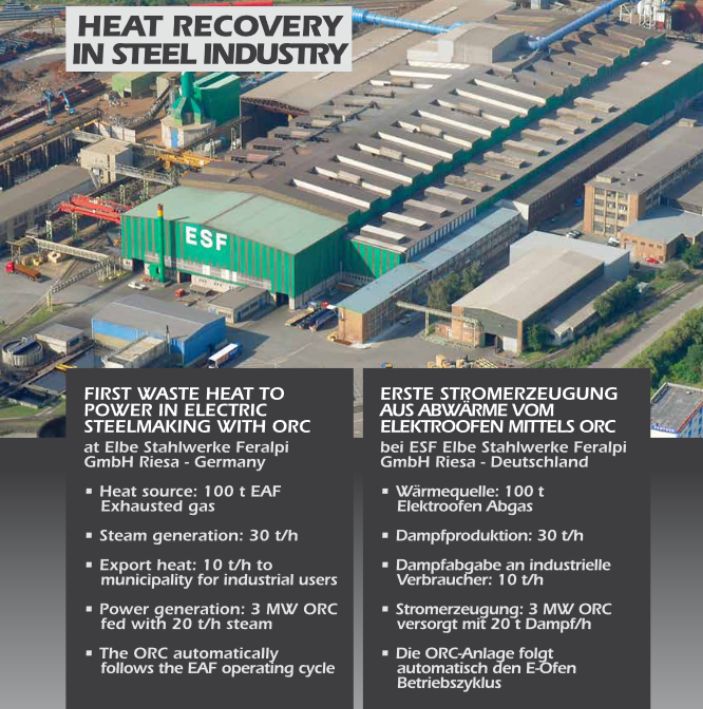

First demonstration of waste heat recovery in steel industry

The project’s key innovative was the installation of the first prototype heat recovery system in an electric arc furnace within the iron and steel industry. Its value was confirmed by the fact that several other studies across the EU were subsequently conducted to evaluate the impact of ORC technology applied to other Energy Intensive Industry sectors.

The project team provided quantitative results of the environmental benefits of the demonstration plant, including reduced greenhouse gas (GHG) emissions. The direct environmental benefits are related to power production, where the prototype enabled savings of around 500 MWh, avoiding the emission of around 190 000 tonnes of CO2. Moreover, a number of potential indirect savings and emission reductions at EU level could also be realised by applying the ORC heat recovery system at large scale in energy intensive industries with the required adjustments (e.g. glass, cement, steel). In light of this, the project estimated that a wide penetration of heat recovery systems on EEIs could be sufficient to allow the achievement of EU 20-20-20 strategy targets concerning CO2 emission reductions.

First demonstration of waste heat recovery in steel industry 0 reviews

Login to Write Your ReviewThere are no reviews yet.